ZCS(Zhongchengsheng) Modular Housing has secured a modular hotel-apartment project for a U.S. California client. Following the completion of preliminary foundational communications, the production of samples for this client’s modular hotel-apartment project has officially commenced. Subsequent to the previous U.S. non-residential commercial project, this undertaking marks another significant milestone for ZCS Modular Housing in expanding into the North American high-end market, while also serving as a crucial catalyst for the company to comprehensively upgrade its overall capabilities.

The North American market imposes stringent requirements on the compliance of construction products, with each state having its own set of U.S. standard systems.

The full implementation of product certification is not only a "pass" for entering the market but also a systematic challenge to the factory’s production processes, supply chain management, and design capabilities.

Since the project’s inception, core U.S. standard compliance requirements have permeated the entire project lifecycle.

From the initial product design phase, ZCS Modular Housing has accurately aligned with the natural environment parameters of the project location. Given California’s frequent earthquakes, strong winds, and seasonal snowfall, the products are required to fully meet local specifications for wind load, snow load, seismic resistance, and wind resistance indices. Based on meteorological data and geological conditions of specific regions in California, the design team has conducted targeted structural optimizations to ensure that core indicators such as the connection strength and overall stability of modular components meet U.S. safety standards, thereby avoiding potential acceptance risks from the source.

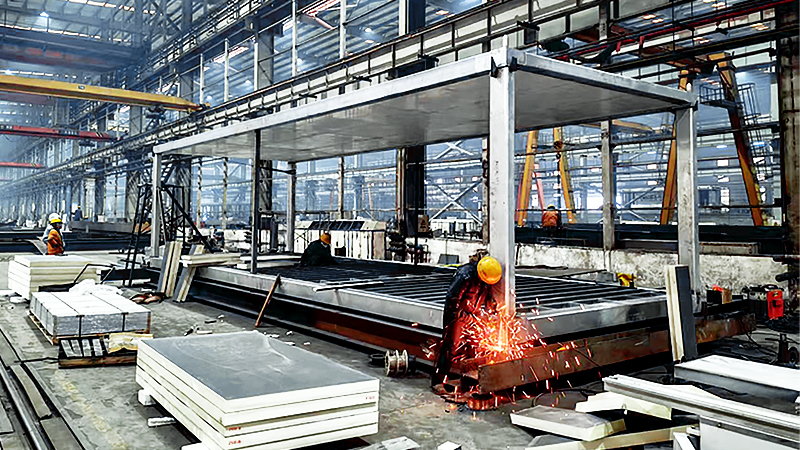

Simultaneously, these requirements have directly driven the iterative upgrading of the factory’s production processes. To meet U.S. standards for product precision and durability, the factory has comprehensively transformed its production links:

•Introduced high-precision CNC cutting equipment, controlling component processing errors within the millimeter range;

•Optimized welding processes, adopting AWS D1.1 standard-compliant welding technology to ensure weld strength and stability;

|

|

•Established a full-process quality control system, with each production step implemented in accordance with relevant ASTM standards—from incoming raw material inspections to finished product factory inspections—achieving standardization and compliance throughout the production process.

The quality upgrade of the supply chain is equally indispensable. Since the previous U.S. non-residential commercial project, the company has conducted rigorous screening and evaluation of upstream and downstream suppliers for prefabricated modular houses. All raw materials and components must provide U.S. standard compliance certificates, and key structural parts are required to pass third-party testing and certification. By establishing long-term partnerships with high-quality suppliers that meet U.S. standard requirements, a stable and reliable supply chain system has been built. This ensures that all supporting products, from steel and plates to HVAC equipment, meet the quality requirements of the North American market, providing a solid guarantee for the successful compliance-based implementation of the final products.

ICC certification includes subdivisions such as ES and NTA, with varying standards across different states. However, ICC certification is of great significance for clients’ products to gain local official recognition and achieve smooth implementation. Taking this California modular hotel-apartment project as an opportunity, the company has established a professional U.S. standard compliance research team to conduct in-depth interpretation of series standards such as ICC and ASTM; optimized the design process by incorporating local environmental parameters and compliance requirements of each state into the initial design phase; and strengthened professional training for production and quality inspection personnel to enhance their ability to implement U.S. standards.

From the production of client samples to the full-process compliance implementation, ZCS has achieved an all-round capability upgrade covering design, production, and supply chain, leveraging the California hotel-apartment project as a fulcrum. This not only ensures the smooth progress of the California modular hotel project but also enables the company to master core technologies and management experience in U.S. standard compliance. It lays a solid foundation for further deepening the North American market and undertaking more high-end projects, establishing a unique competitive advantage in the international track of modular construction.