Tianjin, January 13, 2026 — Today, the certification team from the International Code Council (ICC) officially stationed itself at the ZCS modular housing manufacturing base in Tianjin, conducting a comprehensive acceptance inspection of the factory's production system and residential samples slated for shipment to the United States. This marks the first time a Chinese modular construction enterprise has obtained full-process certification meeting the world's highest standards, establishing a new milestone for "Made in China" to access the global high-end construction market.

ICC certification is hailed as the "passport" of the global construction industry, renowned for its stringent certification process. The acceptance inspection this time covers every stage from raw material procurement and factory production to finished product testing:

All construction materials adopted by ZCS are American standard products certified by ICC-ES (Evaluation Service): structural steel complies with the ASTM A992 standard, wall insulation materials have passed ASTM American standard testing and certification, door and window systems meet NFRC certification requirements, and even every structural screw is marked with a traceable certification code. The certification team spot-checked the certification documents of over 30 types of materials, confirming 100% compliance with American standard specifications.

ICC-Certified Raw Materials

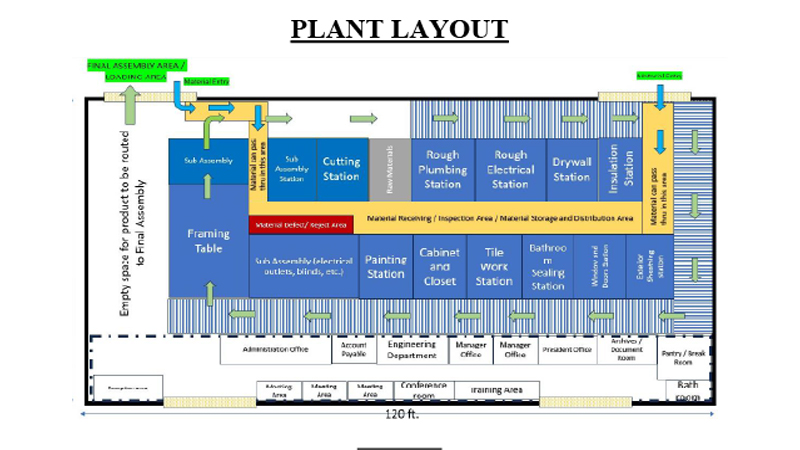

Inside the 120,000-square-meter intelligent factory, certification experts conducted in-depth inspections of every workstation on the production line, ranging from the automatic import of BIM models, precision robotic cutting, and modular assembly processes to real-time data recording at quality control checkpoints. The factory's proprietary "Seven-step Quality Lock System" left a deep impression on the audit team—more than 90% of the assembly work for each module is completed in a closed environment, with the margin of error controlled within ±5mm.

quality control production flow chart

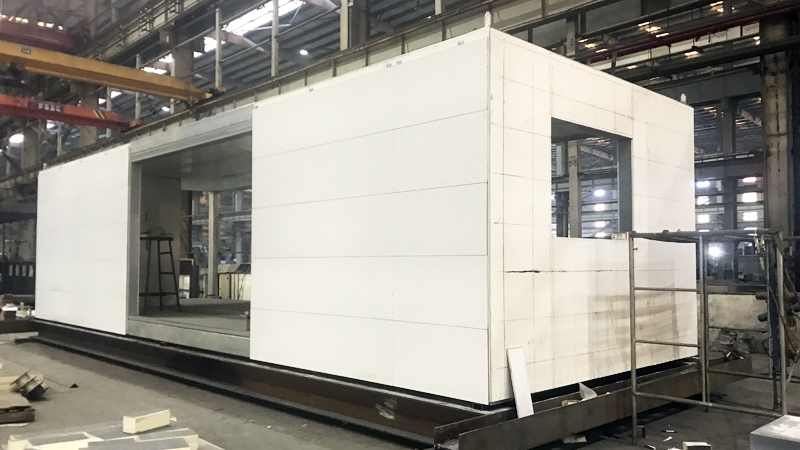

A 40-square-meter residential sample underwent simultaneous acceptance inspection. In addition to routine tests, the certification team also conducted tests simulating extreme conditions: a 30-minute continuous water spray test on exterior walls at a wind speed of 110mph to verify waterproof performance; application of a snow load 1.5 times the designed capacity on the roof; and cyclic loading tests on key connection joints. All test data was transmitted in real time to the ICC data center for analysis.

"What we see is not just a factory, but a complete digital construction ecosystem," stated the ICC certification supervisor. ZCS's independently developed MES production management system can directly convert American standard building codes (IBC, IRC) into machine-readable process parameters, ensuring that every production step complies with regulatory requirements.

The factory adopts a fully enclosed dust-free production environment, enabling modular homes to achieve a level of precision unattainable by traditional on-site construction. IoT sensors built into the walls can monitor the structural health status throughout the building's entire life cycle.

modular house ADU

What does obtaining ICC certification mean for end customers?

Revolutionary Simplification of Approval Processes

Upon arrival in the U.S., certified homes can help homeowners obtain approval from local building authorities, cutting the traditional approval process that takes months down to just 2–3 weeks. Each home comes with an ICC certification document package, including all material certifications, factory inspection reports, and test data, forming a complete compliance certification.

Dual Benefits for Insurance and Financing

ICC-certified buildings qualify for more favorable insurance rates, as insurers recognize their higher quality standards. Meanwhile, mainstream financial institutions offer special financing products for certified homes, allowing down payment ratios to be reduced by 15%.

Visualized Quality Assurance

Customers can use a dedicated ID to query real-time data on every quality inspection point during the home's production process, including weld flaw detection reports and airtightness test results—transparent information that traditional construction cannot provide.

Reduced Long-term Maintenance Costs

The standard warranty period for certified materials is generally extended by 40%, and all replacement parts can be sourced locally in the U.S. through standard channels, completely resolving the spare parts challenge associated with cross-border maintenance.

The certification team of the International Code Council (ICC) conducts acceptance inspection of the factory

Charlie Chai, CEO of ZCS Modular Housing, stated at the acceptance inspection site: "Obtaining ICC certification is not the finish line, but a new starting point. Based on this, we will promote the two-way integration of Chinese modular construction standards with international standards."

It is reported that the first batch of certified modular homes will be shipped to California in March 2026 for local ADU (Accessory Dwelling Unit) modular housing projects. These homes are 95% completed in the factory and can be hoisted and installed within 72 hours of arrival at the site, truly achieving a "move-in ready" experience.

As the global housing shortage becomes increasingly acute, modular construction is emerging as a new industry trend due to its high efficiency, environmental friendliness, and controllable quality. ZCS's successful experience in obtaining ICC certification provides a replicable model for the international upgrading of China's construction manufacturing industry—not just simple "product export," but "standard export" and "brand export."