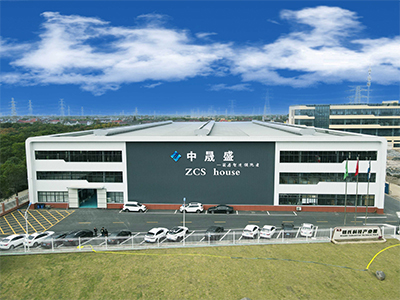

Zhongchengsheng Modular Housing’s factories are large-scale, modern, and technology-intensive manufacturing bases integrating industrialized construction and intelligent manufacturing. Branches are located in four regions: Suzhou, Shandong, Tianjin, and Anhui.

|

|

|

|

| Suzhou | Shandong | Tianjin | Anhui |

• Floor Area: Each factory covers an extensive area, generally over 50,000 to 100,000 square meters, integrating production workshops, raw material warehouses, finished module storage areas, R&D centers, and office spaces.

• Positioning: Focus on providing end-to-end modular building solutions for the market, with products widely applied in:

◦ Commercial Sector: Modular hotels, office buildings, and commercial stores.

◦ Livelihood Sector: Modular schools, hospitals, and nursing homes.

◦ Residential Sector: Affordable housing, apartments, and high-end custom residences.

◦ Special Sector: Temporary command centers, construction site barracks, and emergency mobile cabin hospitals.

Suzhou ZCS currently operates four major production bases in Suzhou; Shandong; Tianjin; and Anhui. All have achieved large-scale smart manufacturing production lines; with a prefabrication rate as high as 95%, significantly reducing on-site installation time and labor costs for housing construction projects.

|

|

Quick-assembly production capacity currently stands at 2,000 units per month; modular production at 200 units per month; and foldable expansion units at 200 units per month. Leveraging the powerful advantages of “cost reduction, speed enhancement, and quality assurance,” we can address the housing shortage in North America.

|

|